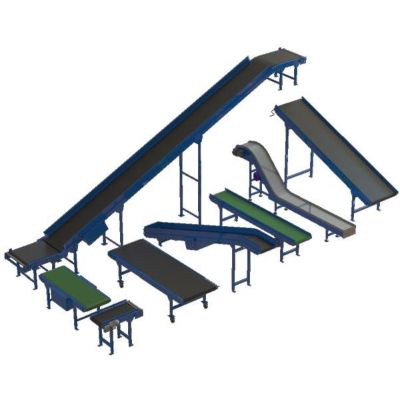

Conveyors

Conveyors are manufactured to offer a way of transporting items from one area to another and range from basic gravity fed rollers through to automated belt drive systems. Our popular telescopic vehicle loading and unloading systems are designed to quickly empty a container for 40 foot truck.

Conveyor Spares

Spares for existing conveyors or parts to manufacture your own conveyor or ball transfer unit. Available from stock or manufactured to match existing requirements, Merlin can help keep you moving.

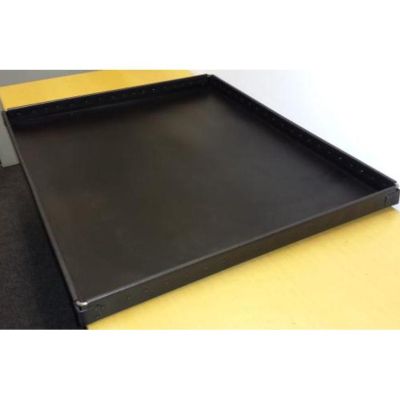

Conveyor Trays

Made to order conveyor trays are designed with flat bases to run on most conveyor systems from skate roller track to belt conveyors and allow smaller items not normally suited to conveyors to be transported.

Different Types of Conveyor Systems

A conveyor system simply takes a product from point A to point B. As conveyors have evolved along with automation and I.T. the systems that can now be implemented during the product's trip are almost limitless.

Flexible Conveyors

Flexible conveyors are used in food packaging, case packing, and pharmaceutical industries where a mobile conveyor system that can be directed around obstacles has appreciable benefits.

Gravity Feed Conveyors

Gravity Feed Conveyors are, by far, the most popular and simple way of moving a product from A to B by the use of the product's own weight. Gravity allows the items to travel at various speeds depending on the pitch.

Line shaft Conveyors

For ultimate flexibility of design and usage, the XU series of Line shaft conveyors cannot be beaten. These conveyors are suitable for light applications up to 20 kg, such as cardboard boxes and tote boxes.

Lorry Loaders and Unloaders

Discover a versatile range of lorry loaders and unloader conveyors designed to meet your unique needs. Available in Fixed, Flexible, Powered, and Mobile configurations, our conveyors are meticulously crafted to cater to a diverse array of requirements. Whether you're dealing with parcels or mattresses, our conveyor systems are engineered for the secure and efficient loading or unloading of vehicles, spanning from transit vans to ISO sea containers. Whatever your cargo, our conveyors provide a tailored solution for swift and safe material handling.

Pallet Conveyors

Pallet conveyors are generally used for moving heavy loads, though it can equally be used where the working environment demands a rugged construction. Manual and motorized versions available.

Powered Belt Conveyors

Powered belt conveyors are one of the most popular conveyor systems in the world for moving items from one space to another. We have various smooth and ribbed belts, along with belts for the food industry. The powered belt conveyor frames can be supplied in steel and stainless steel.

Stainless-Steel Conveyors

Stainless-steel conveyors are predominantly for the food industry. These are a small selection of the most popular stainless conveyors, though we can supply a much wider range.

Telescopic Gravity Track Conveyor

Telescopic Gravity Track Conveyor. A simple arrangement of sections of gravity roller track linked together by sliding transfer sections to provide a useful means of loading and unloading vehicles. Or moving goods within the warehouse or stores and without the need of power, these gravity conveyors can be used anywhere.

Workflow Solutions for Production Areas

On assembly lines, efficient material handling is crucial to productivity. Since transportation does not involve processing the item, transport times should be minimized. With properly planned material flows, buffer sizes are minimized and thus the WIP (work in process) value reduced.