Information on lockers and helpful tips on locker room design guidance and helping maximize storage solutions for staff and visitors. Most buildings have been designed without thought for personal storage space. Education in particular.

Guidance to Locker Room Design Important factors to consider.

Metal lockers are not intended for use in damp or wet areas. Under the Workplace (Health, Safety and Welfare regulations 1992) employers are required to provide suitable and sufficient accommodation for workwear and personal clothing. The Personal Protective Equipment at work regulations 1992 also require the provision of suitable storage to protect personal protective equipment from damage, contamination, or loss.

Guidance to locker room design

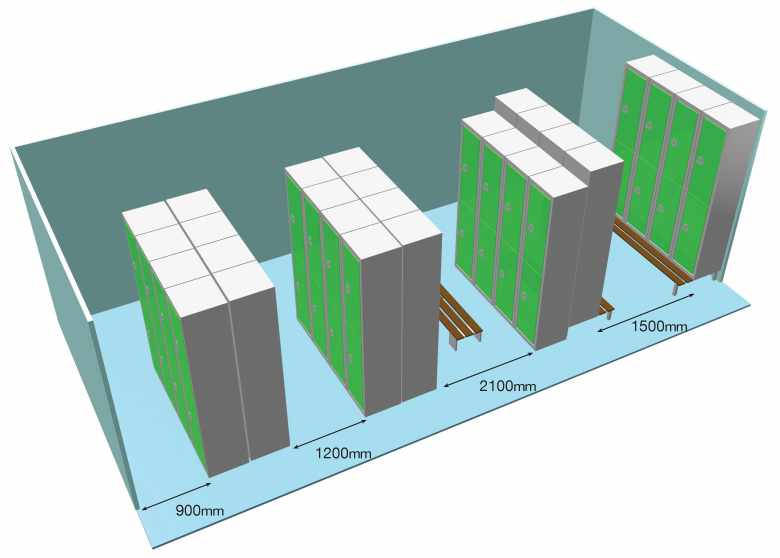

Minimum distances to allow clear movement of users in gangways.

Important factors to consider on locker room design and choice of locker.

The size and configuration of the locker compartment will be determined by the items to be stored e.g. the need to hang garments, size of bags/holdalls, the storage of motorcycle helmets and footwear etc.

- Is there a need to keep workwear separately from personal clothing.

- If hygiene is essential, consider a factory fitted sloping top option on lockers.

- This prevents an unwanted build up of dirt and debris and also encourages storage within the locker and not outside. Locker stands can provide cleaning access to beneath the locker.

- In dry changing room environments, lockers can be floor mounted. In wet areas, it is critical to raise the locker off the floor using locker stands.

- Check floor surfaces are level, lockers are designed to be floor standing. To overcome uneven floors, locker stands are supplied with adjustable feet.

- If users are changing footwear, it would be useful to offer bench seating or an integral seat and stand option.

- Is there a need to air damp clothing – then consider lockers where compartments are big enough to hang garments. Also, consider perforated holes in doors to increase air circulation.

- Type of lock required, key cam lock, padlock type fitting, £1 coin return or token return lock, 4 digit combination lock options available. Remember during installation to database keys to a locker compartment for easier key management.

- Consider additional locker accessories, e.g. hanging rail, sloping top, number plates, extra keys etc.

- Is there a need for locker compartments to be visually monitored. Perforated and vision panel doors allow inspection from outside the locker.

- Factors relating to the positioning and off-loading of lockers should be considered, e.g. will extra labour be required. Nested lockers are more difficult to manoeuvre than single lockers.

- Check if delivery vehicle access is sufficient.

- Coloured door requirements – most lockers have a standard carcass finish, normally grey. Later designs offer a wide range of door colours.

- If you require advice, contact Merlin Industrial Products – suppliers of lockers for more than 30 years.

Moving lockers outside the main building

Lockers can now be supplied manufactured using plastic which means that they are suitable for wet areas or, under awnings outside the school's main building, as per the image above.

Using new or existing shelters can greatly enhance your personal storage space, and limit the traffic congestion within corridors.