The night owl self righting bollard can be illuminated for nighttime use and offers a flexible solution for road sign-age with the current UK legislation notes below. The Night Owl bollard has now passed BS EN 12767:2007 & BS 8442:2006.

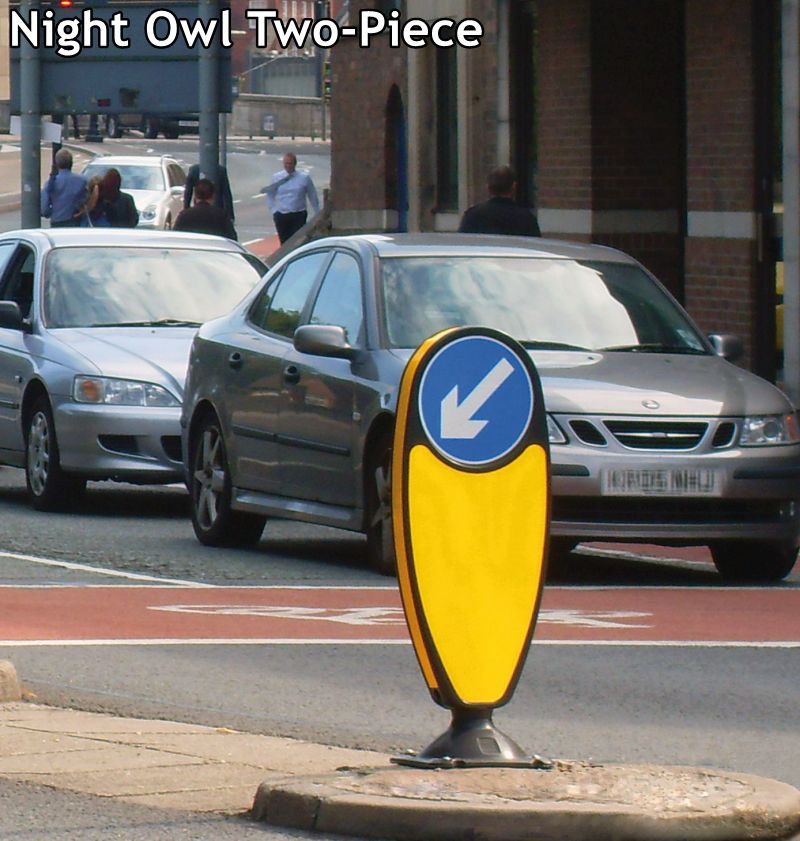

Two-Piece Night Owl Bollard

The Night Owl Bollard is comprised of two components; a universal ‘Bounce-back’ Base unit designed to self-right the sign after impact and the Night Owl sign and graphics (Conspicuity panels) designed to provide high visibility and durability in areas without street lighting.

Two-Piece Night Owl:

The reflex material of the base combined with the rigid polyethylene of the sign ensures that the bollard will withstand multiple impacts and return to upright without damage to the reflective surfaces, the sign or the base; thereby saving on expensive replacement costs. The reflectors are also recessed to further reduce potential damage with vehicle impacts.

Unique ‘dome’ shaped Base gives reliable bounce back performance irrespective of the type of impact (side scrape, side swipe or front on).

Base made from tough ‘Reflex’ material capable of withstanding impacts up to 70km/h to return the sign to an upright position ensuring the hazard remains clearly marked.

Moulded-in screw thread on the top of the Base means that no mechanical components are used on the sign.

Strong rigid construction of the sign withstands damage from the ‘trampling’ action of wheels running over the top of the sign.

The Sign section can be moulded in most colours including stone effect/mottle finishes for environmentally sensitive areas. See ‘Colour Options’ pop-up for the complete range.

The Two-Piece Night Owl Sign can be easily removed and replaced in under a minute reducing danger to Highway Contractors and inconvenience to road users.

No power supply required, therefore road closure can usually be avoided during installation.

Fluorescent, retroreflective material used as standard for high visibility.

Retroreflective panel on the Sign edge provides best in class visibility: 0.045m2 (BS 8442 requires a min of 0.02m2)

Recyclable material used throughout; suitable for environmental re-use.

Adapter plate available to allow the Base to be fixed to many existing mountings. See ‘Fixing Options’ pop-up below for all fixings.

Single or Double sided options

Passed – Night Owl conforms to BS 8442:2006 (14) for Retro Reflective Self Righting Bollards

Passed – Night Owl conforms to BS 12767 Passive Safety of Non Harmful Structures (70,NE,4)

Passed – Night Owl conforms to BS EN 12899-2:2006 5.6.4 Torsion Test

The Background:

Much confusion has arisen over the changes in CE marking requirements regarding illuminated self-righting bollards (SRBs).

Illuminated self-righting bollards were initially to be classified under BS EB 12899 pt 2 but no existing SRB met the requirements . This meant that all current illuminated SRBs would not be able to be sold after July 1st 2013.

Bollards meeting the dimensional requirements of BS EB 12899 pt 2 will not pass under a vehicle and return to upright. ARTSM (Association for Road Traffic Safety and Management) contested the decision successfully with BSI.

It was agreed that a revision to BS 8442 pt. 14 be undertaken to include SRBs “enhanced by illumination”. The requirements for illuminated SRBs will continue to defined by the current BS 8442 pt. 14 until the revision is approved and released.

The Current Situation (November 2013): Illuminated Night Owl does not require CE Marking as it is tested to, and complies with, BS 8442 pt. 14.

Illuminated Night Owl Benefits:

• Self-righting performance causes less damage to vehicles and bollard alike.

• Proven at MIRA to be passively safe to BS EN 12767:2007 100 NE4

• Rigid sign carrier reduces the cracking and crazing found on the graphics of inferior products.

Hybrid Rotational Moulding

“Combining heterogeneous materials in a single rotational moulding, each having different and complementary performance characteristics.”

Leafield Environmental, has evolved and patented process methodology that combines different polymers in a single part moulding. Each polymer maintains its own individual performance characteristics when the moulding is complete.

An example of this can be found in Leafield’s new one piece Night Owl keep left, self-righting sign bollard. The neck of the bollard is made from a durable reflex material that provides the bounce-back capabilities of the bollard.

The body is moulded from a high rigidity polymer that offers several benefits including providing a stable surface for signage and conspicuous panels. Proven at MIRA to be passively safe to BS EN 12767:2007 100 NE4, the one piece Night Owl conforms to BS relevant British Standards and can withstand repeated impacts at up to 100 kph and the ‘trampling’ action of wheels running over the top of the bollard.

Some other similar bollards are manufactured entirely from reflex type material with less than satisfactory results. The high flexibility of the reflex material causes signs to de-laminate over time and if and when the bollard is struck by a vehicle the air pressure within the bollard instantly increases. The bollard momentarily expands like a balloon causing signs and conspicuous panels to crack, craze and come unstuck in a dramatic fashion.

Leafield designers consider that the process can bring benefits to a number of projects where material performance requirements are not consistent throughout the moulding.

NightOwl Bollard Leaflet

NightOwl Bollard Installation Guide

NightOwl Bollard Technical Drawings

One Piece NightOwl Bounce Back Bollard

For an economical, one piece, self-righting “keep left” bollard that incorporates new patented manufacturing technology that the Company claims significantly improves product performance.

Branded Night Owl, the surface mounted, one-piece bollard is rotationally moulded in a single operation but using two different polymers at the same time. The neck of the bollard is made from a durable reflex material that provides the bounce-back capabilities of the bollard.

The Night Owl body is moulded from a high rigidity polymer that offers several benefits, including providing a stable surface for signage panels. Proven at MIRA to be passively safe to BS EN 12767:2007 100 NE4, the one piece Night Owl conforms to relevant British Standards and can withstand repeated impacts at up to 100 kph and the ‘trampling’ action of wheels running over the top of the bollard.

Many other similar bollards are manufactured entirely from reflex type material, with less than satisfactory results.

The high flexibility of the reflex material causes signs to delaminate over time and if and when the bollard is struck by a vehicle the air pressure within the bollard instantly increases, the bollard momentarily expands causing signs panels to crack, craze and come unstuck in dramatic fashion.